ATE

Electric And Electronic Components Test System and Solution

Electric And Electronic Components Test System And Solution

Our company supplied test system and solution for Product’s Electrical characteristics of many customers such as Samsung Electro-Mechanics, Samsung Electronics, Fairchild, LG Chem, LG Innotek, LS Industrial Systems, Omron, Cukoo, Dyson, Bosch, Coway, Rinnai, SK magic, Epson, Cheil Industries, Autonics, Schneider and etc. Through this experience, we configure pattern, color, power, FPD test solution and supplied test equipment for home appliances such as TV, Microwave, Washing machine, Monitor, Laptop, Printer, Refrigerator, Induction range, Electric rice cooker, Vacuum cleaner, Computer, Audio, Beam projector, POS system, Scanner, Electric tool, DVR, Digital camera, Water purifier, Oven, Boiler, Air cleaner, Air dryer, Electric fan and etc. By applying our equipment, we have built systems in all lines from receiving material such as product reliability test and performance test to product quality test and preshipment quality test. Also we build system by applying our products for parts manufacturer’s passive/active parts test, various semiconductor chips and power parts test.

Key Features

- Electric And Electronic Component test

- Lifetime Cycling test

- Independent Protection

- High precision measurement

- Simultaneous test of multi-channels

- Providing standardized test item

- Precise characteristic test with low ripple and noise

- Data acquisition and providing environmental test by combination with temperature and humidity chamber

- Graph display of voltage, current and temperature in real time

- Various loads simulation function

- Providing option according to user and DUT

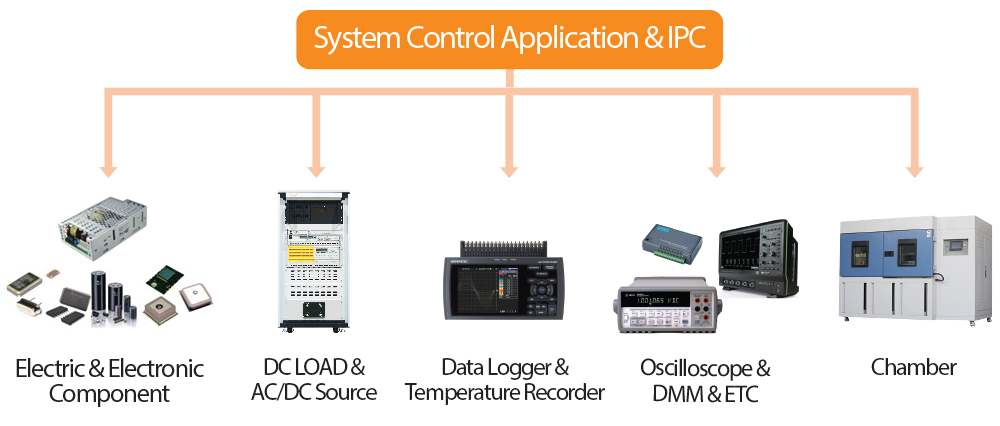

System Integration Diagram

Application

- Electronic parts manufacturer

- DC-DC Power manufacturer

- AC-DC Power manufacturer

- Switch & Relay manufacturer

- Charging/Discharging(Capacitor&Battery) test

- PMIC(Power Management IC) test

- Diode parts test(Vf, Vrb, lr etc.)

- Harness and Connector test

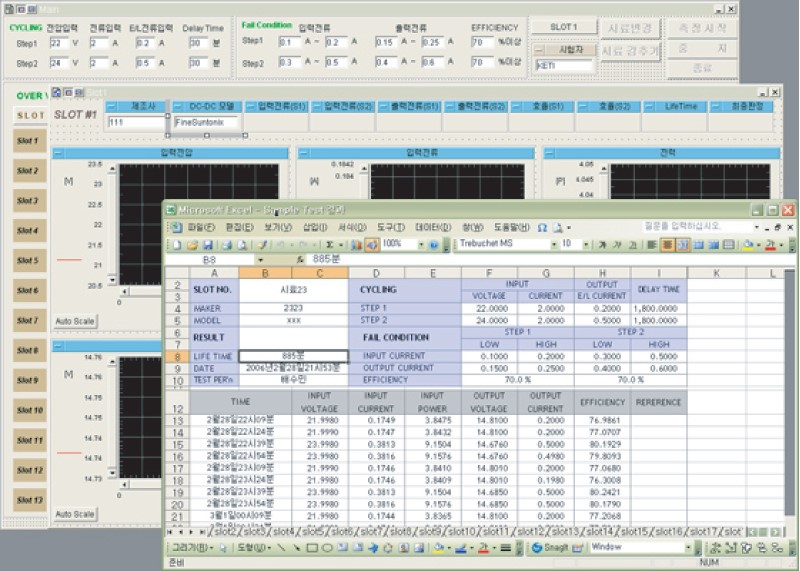

Software

- Voltage/Current setting for each channel

- Supporting Multi channel as per customer request

- Voltage/Current setting for each channel

- Controlling Temperature, Humidity by connecting chamber

- Various Protection such as Over voltage protection(V), Under voltage protection(V), Over current protection(A), Over temperature protection(℃),

Channel data in data logger(Option), ΔV /+ΔV protection(V), +ΔI /-ΔI protection(A) - Life cycling and Durability cycling

- Providing result by graph and saving data for each channel

- Add functions as per customer request

Main Customer